UL Labels

What you need to know about UL labels

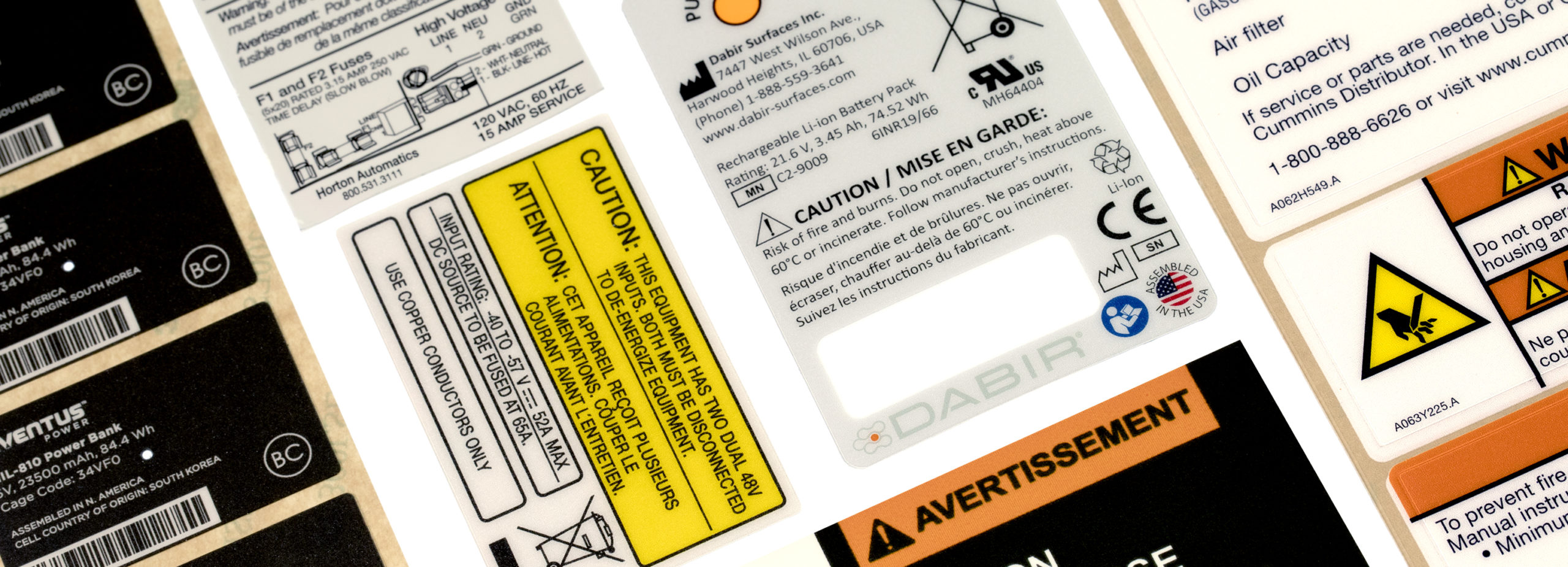

UL Labels, or Underwriters’ Laboratories labels, are used to display safety-related information on products. This can vary from warnings, electrical ratings and installation instructions to any number of other important pieces of information to be displayed to the consumer.

At MSI, we have been working with UL and its Canadian equivalent, CSA, since 1975. Suffice it to say we know our way around a UL label.

Currently MSI has UL and CSA certifications covering polycarbonate/Lexan, .002 pressure sensitive polyester, .004 vinyl and many different types of paper. We have certifications for screen printing, digital, hot stamp and thermal printing. These certifications include environmental conditions such as chemical exposure, heat and cold resistance and indoor/outdoor.

Let’s dive into more of the specifics of UL and how MSI can help.

What is a UL label and why is it important?

Underwriters Laboratories is an organization that focuses on safety, whether that be fire, electrical, performance-based or any other form of potential hazards. Therefore, UL labels indicate that the product and product label in question have been safety tested and approved to the designated Underwriters Laboratories standard — which is the gold standard. It tells consumers that your product is certified safe for use.

But there’s a little more to it than that. There are four levels of UL certification, based on the type of product you have.

4 levels Of UL certification

In the industry today, there are four different levels of UL certification:

- PGDQ2: Marking and Labeling Systems

PGDQ2 is the highest level of UL label certification and requires the label manufacturer to get the adhesive, base material, printing system and lamination approved as a complete system. This high-standard label is typically used for warning, danger or caution labels that must stay legible for the entire life of the product.

At MSI, we are required to identify these types of labels with our manufacturer ID and recognition number on the package of labels or in the roll core. Without this label on the packaging, a UL label inspector can shut down a manufacturing line.

- PGGU2: Materials

PGGU2 are traditionally informational type labels, and therefore don’t need the stringent certification of the warning, danger or caution labels. This certification requires that material manufacturers only have the UL label on the material. The supplier does not need to go through additional label testing.

- PGJI2: Printing Material

PGJI2 are blank labels that are printed on thermal printers, typically by the OEM in their facility at the time of manufacture. This certification requires that both the product label material and the thermal ribbon be UL tested for compatibility as a complete system.

- PGIS2: Limited Use

PGIS2 are limited-use category covers, labels, cord tags and placards that have been evaluated for UL compliance. These are labels with less stringent requirements and are mainly used with products that are covered by relaxed standards such as enclosures for electrical equipment, power supply cords or gate operators.

We can help

At Marking Systems, we have been working with UL and its Canadian equivalent, CSA, since 1975. With all of that experience behind us, we can confidently say we’re the experts in getting it right for our customers. For a listing of all of our UL and CSA certifications, please don’t hesitate to get in touch.

Let our product label experts guide you to your solution today!