Dead Front and Backlit Overlays

At Marking Systems, custom overlay manufacturing is one of the main parts of our business. They’re the most recognizable component on your product and give it the “look.” They’re your first impression! And you know what people say about first impressions. That’s why overlays are so important. But that’s not the only reason.

Sure, they’re eye-catching, but overlays are critically useful, directing the end-user around the keypad, often representing what each button will do. Custom color matching and branding are a key component, and we’ve got the technology and experience to do the job. We can also help your designers choose the best materials and functionality for your application. Using Datacolor Software and instrumentation ensures MSI can match your color and maintain consistency run to run. We always match color back to the standard to eliminate “color creep.”

And this might be obvious, but you don’t want your overlay to ever fall off. Our expertise in adhesives means you never have to worry about that. We stock adhesives for hard-to-stick powder coat paint or plastics. Being a 3M Preferred Converter means MSI has a huge stock of 3M laminating adhesives such as 3M467MP, 468MP, 9471LE AND 9472LE to name just a few.

We work with any type of overlay, including screen printed, digital printed, custom textures, transparent inks, backlit/dead fronts, thick lenses, metallics and embossing.

Here, let’s go into a bit more detail about dead front and backlit overlays.

What is Dead Fronting?

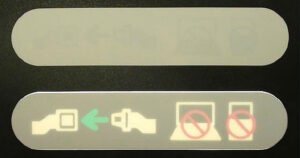

The term “dead fronting” in the printing industry refers to an icon or feature that is hidden from view until an LED light illuminates the symbol or text. When the light source is on, the hidden graphics are revealed. When off, the graphics are hidden, or “dead.” This allows you to illuminate only the graphics or symbols in use at the time. Your car dashboard is probably the most common application for dead front overlays. The main concept is to only illuminate the graphics or symbols you want the customer to see at any one time. For instance, you only see the seat-belt indicator light if you are not wearing your seat belt.

In contrast to the static graphic options of the past, dead front overlays give the benefit of a less cluttered look to your overlay.

The Manufacturing Process of Dead Front Overlays

The printing of dead front overlays can be complicated. It involves printing, maybe several passes of ink, in order to achieve the proper level of opacity and create the graphic elements.

Cutting is the next critical process, and Marking Systems Inc. has numerous choices. Our Zund digital cutter (for prototype/short production runs) uses camera registration to ensure the graphics are placed over the light source within +-.010 tolerances. This method is preferred for prototype runs. Production runs are processed on our Preco die-cutting line that also has camera registration ensuring +-.010 tolerances.

Backlit Overlays

The backlighting of graphic overlays can create a dramatic visual effect, especially in low-light environments like an airplane cockpit. Traditional back-lighting utilizes incandescent or LED lights behind the graphic overlay. Often, these light sources are assembled on a PCB or attached to a sub-panel.

How it works:

- When the light source is off, the panel/graphic overlay looks like a regular overlay, but with some graphic elements hidden.

- When the light source is on, the hidden graphics are revealed, providing specific information for the given situation.

Whether it is dead front or backlit overlays, let the product label printing experts at MSI help. We excel at finding cost-effective solutions for our customers.

Let Marking Systems Inc help with your next Nameplate Project.

Call MSI at 972-895-3433 and let our label printing experts help.

Note about rapid prototyping: If you have an overlay you think might benefit from “dead fronting” please contact your MSI SCR or sales rep and ask about our Rapid Prototyping Program. This innovative program makes it inexpensive, quick and easy to see physical samples before deciding to upgrade the look of your overlay.