Understanding UL Burn Testing

At Marking Systems, the safety of our products is a top concern. Our materials for labels and overlays are rigorously tested so we know they’ll stand up to a variety of temperatures and conditions. One of the most crucial tests out there is the test for flammability.

Our materials must pass the UL 94 test standard. What is that, exactly? Here’s more information about UL 94 and why it’s a standard we won’t compromise on for the safety of our products — and our customers.

What is UL 94?

UL 94 stands for “Underwriters Laboratories test standard 94.” UL 94 is the gold standard for flammability in plastic materials. It measures a whole host of factors including:

- How quickly it ignites

- How quickly the fire spreads

- How long the fire endures

- How difficult (or easy) it is to put out the fire

- Toxic gas that’s emitted

In very basic terms, it tests for if and how quickly a material will catch fire. It’s especially important for plastic labels that are going to be used on things like electronics and appliances, where heat can occur. The last thing anyone wants is a label or overlay to catch fire because of that heat. This testing ensures it won’t.

The UL 94 process involves testing the material in different conditions, each with a different rating number, including 94HB, 94V, 94VTM, 94V5, 94HBF, 94HF and Radiant Panel.

We are most frequently asked by OEMs to use materials rated for UL 94HB, 94V or 94VTM. Let’s look at those in a little more detail.

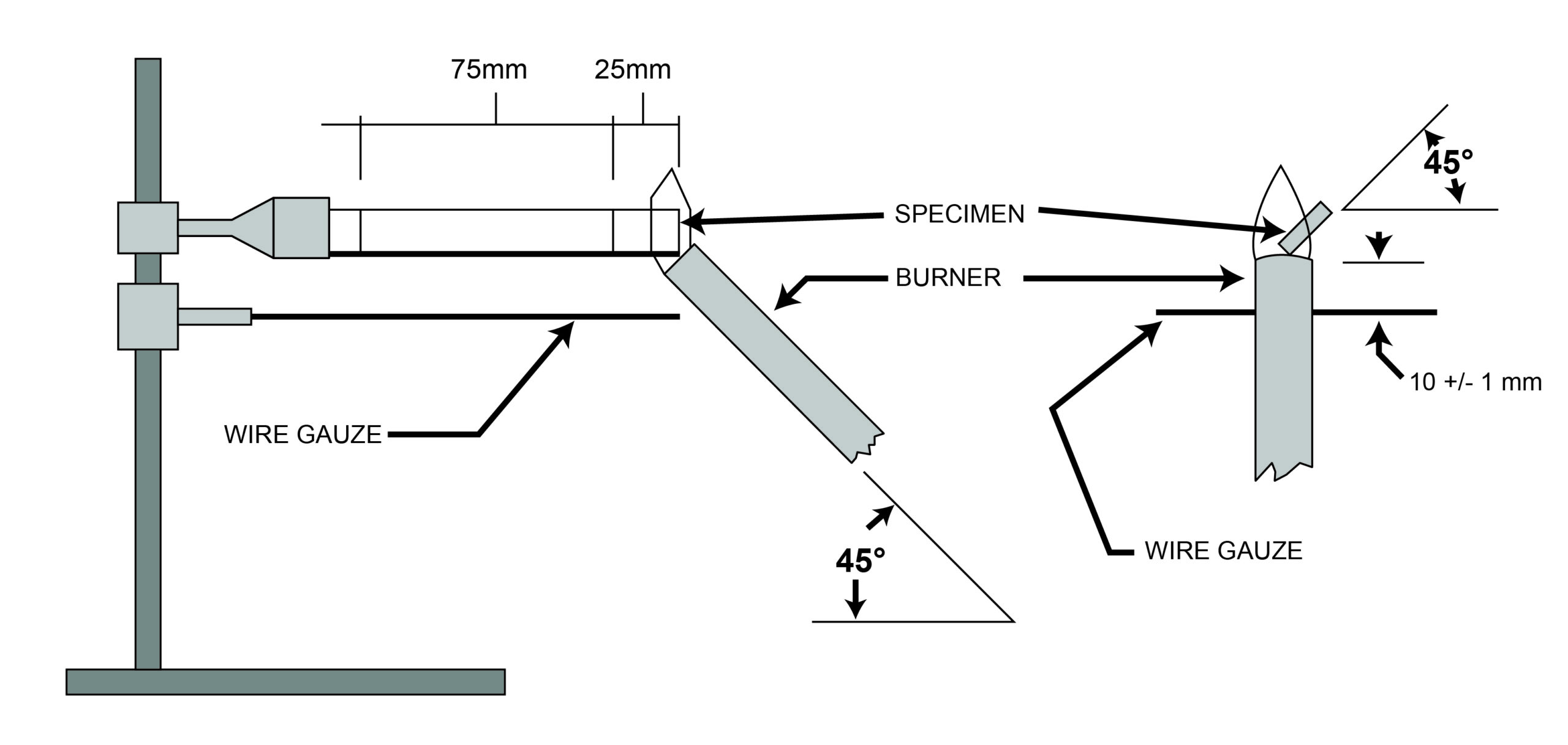

94HB (Horizonal Burning Test)

The 94HB test is a horizontal burning test that is considered the easiest to pass. The material is oriented in a horizontal position and exposed to a flame. To be rated 94HB, a material with a thickness between 3 and 13mm must burn at a rate of less than 40mm per minute.

94V (Vertical Burning Test)

This test, as its name implies, involves orienting a material in a vertical position and exposing it to a flame. This is the standard typically required for portable, unattended, intermittent-duty household appliances. For the 94V, the material is tested in its new state and its aged state. So, how does it hold up when it’s brand new versus when it’s aged a bit? A flame is applied to the sample for two 10-second intervals, separated by the time it takes for the flaming combustion to cease after the first application. They also check for drips during this test.

The test includes three classifications, 94V-0, 94V-1 and 94V-2. The UL 94V-0 is the highest burn rate, meaning the product label material is very unlikely to catch fire.

94VTM (Material Vertical Burning Test)

Product label materials that are very thin (approximately 10 mil) may distort, shrink or flex during the 94V test. These materials can be tested using 94VTM — the thin material version of the vertical burning test. For this product label test, the specimen size is 200mm x 50mm (8″ x 2″), and the two flame applications have a duration of three seconds instead of 10.

At Marking Systems, we use only the materials that meet these rigorous UL standards. We don’t compromise on safety. For more information, give us a call at 972-475-0770 and talk to our product label experts.

UL will generally accept a VTM rating of similar level where a 94V material is required i.e., 94VTM-0 = 94V-0, 94VTM = 94V-1, etc. UL does, however, reserve the right to make a determination on which rating a material should have based on the application.

| Criteria Conditions | 94V-0 | 94V-1 | 94V-2 |

| Total flaming combustion for each specimen | |||

| Total flaming combustion for all 5 specimens of any set | |||

| Flaming and glowing combustion for each specimen after second burner flame application | |||

| Cotton ignited by flaming drips from any specimen | NO | NO | YES |

| Glowing or flaming combustion of any specimen to holding clamp | NO | NO | NO |