The Science of Label Adhesion: Why Labels Stick (or Don’t)

Durable product labels are essential for product identification, branding, and compliance. However, even the best labels can become ineffective if they don’t adhere properly. In this blog post, we’ll explore common reasons for label adhesion problems and offer solutions to help you keep your labels in place.

Why Labels May Not Stick

- Incorrect Adhesive: Using the wrong adhesive for your application surface can lead to premature detachment.

- Surface Changes: Changes in the surface material or finish, such as paint or plastic composition, can affect adhesion.

- Surface Contamination: Dirt, grease, or other contaminants can interfere with adhesive bonding.

- Improper Application: Insufficient pressure or incorrect application techniques can weaken the bond.

- Temperature Extremes: Adhesives may not perform optimally in extreme temperature conditions.

Troubleshooting Tips

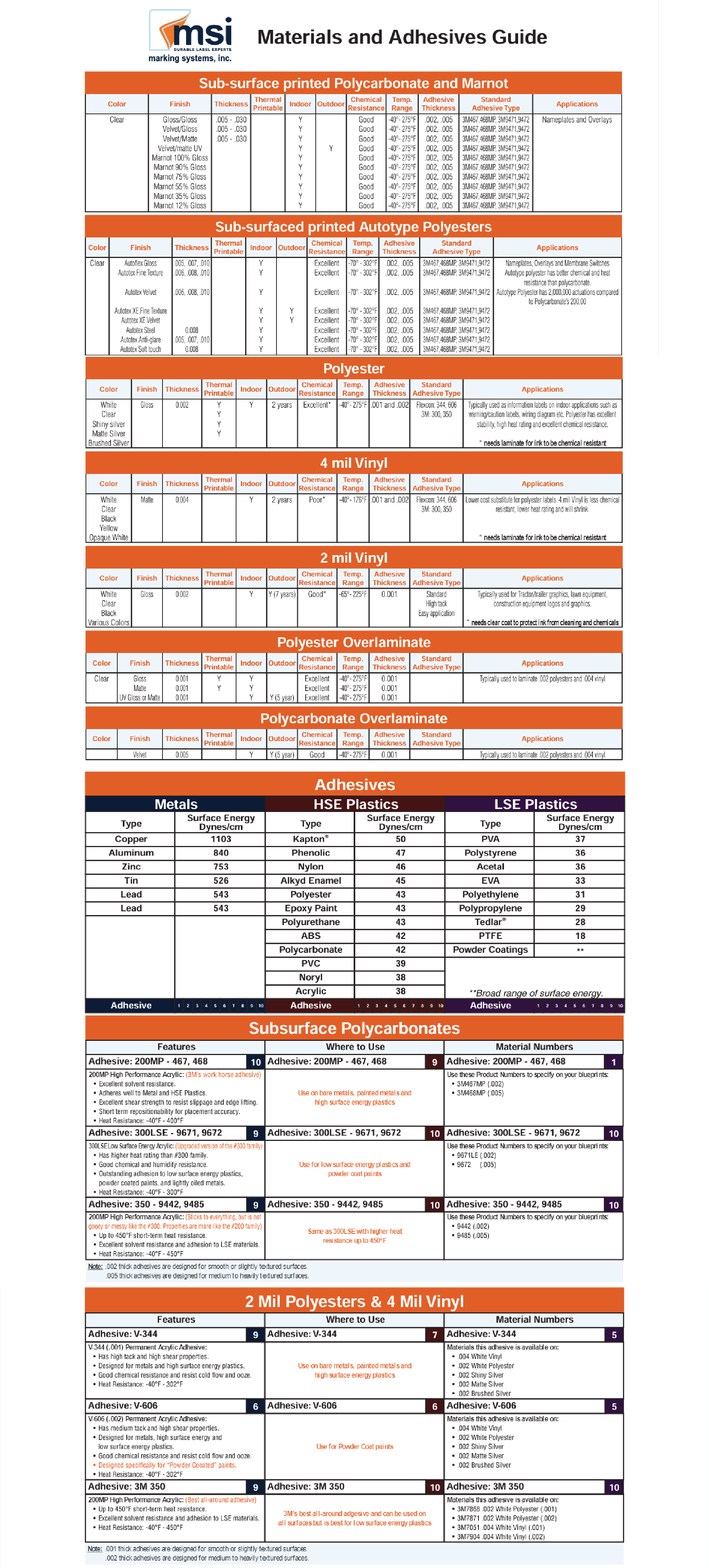

- Evaluate the Adhesive: Ensure you’re using an adhesive designed for your specific surface type and application conditions. 3M has a very useful adhesive selection guide.

- Inspect the Surface: Clean the surface thoroughly to remove any contaminants. 3M recommends cleaning with a 50:50 mixture of isopropyl alcohol (IPA) and water.

- Apply Correctly: Use firm pressure to ensure proper contact between the adhesive and the surface. 3M recommends using 15 psi be used in application.

- Consider Temperature: If operating in extreme temperatures, choose an adhesive that can withstand those conditions.

- Bonding time: 50% after 20 minutes, 90% after 24 hours and 100% after 72 hours.

Understanding Label Adhesives

Label adhesives are typically designed for three types of surfaces:

- Metals: Easy to adhere to due to high surface energy.

- High-Surface-Energy Plastics: Include materials like Kapton, polycarbonate, nylon, polyurethane paint, ABS, and epoxy paint.

- Low-Surface-Energy Plastics: Include materials like polystyrene, polyethylene, polypropylene, and powder coat paints. These are the most challenging surfaces to adhere to.

Need Expert Assistance?

If you’re still experiencing label adhesion issues, our team at Marking Systems Inc. is here to help. As a 3M Preferred Converter, we have direct access to global 3M support and material specialists. This partnership offers several advantages:

- Preferred Pricing: We provide competitive pricing on innovative 3M materials and adhesives.

- Rapid Lead Times: Benefit from faster turnaround times for popular 3M products.

- Extensive Inventory: Our extensive inventory ensures quick delivery of samples and prototypes.

Don’t Let Label Adhesion Problems Slow You Down. Contact Marking Systems Inc. today for expert assistance and reliable solutions.

For Existing Customers: Please reach out to your dedicated MSI/MSD Customer Service Representative (CSR) by phone or email your initial blueprint directly. We’ll promptly arrange a brief 10–15 minute consultation with our R&D Director, Razvan Datcu, to explore innovative solutions tailored to your needs.

For New Customers: To kickstart your project, simply visit our homepage and press the contact button to share your drawings and requirements. Alternatively, feel free to call at (972) 475-0770 for personalized assistance.