Marking Materials & Labeling Solutions

At Marking Systems, Inc. we are industry experts at Custom Designing and Rapid Prototyping Labels, Overlays, Nameplates and Membrane Switches, with knowledge and industry know-how from our more than 50 years in the Durable Label business.

We are a proud 3M Preferred Converter, one of only five printing companies in the U.S. granted that designation, and the only one who is also a Preferred Die-Cutter. We are also an ISO9001-2015 company with all the certifications a manufacturer requires.

Quality runs through everything we do. You can always trust you’re getting the best advice, materials and the most cost-effective solution for your application.

About those materials. We've been around long enough to know that a company like ours is only as good as their materials. That's why we use only the best. Here's more information about the materials we use.

For more detailed information, or for a copy of our Materials and Adhesives sample book, please contact us.

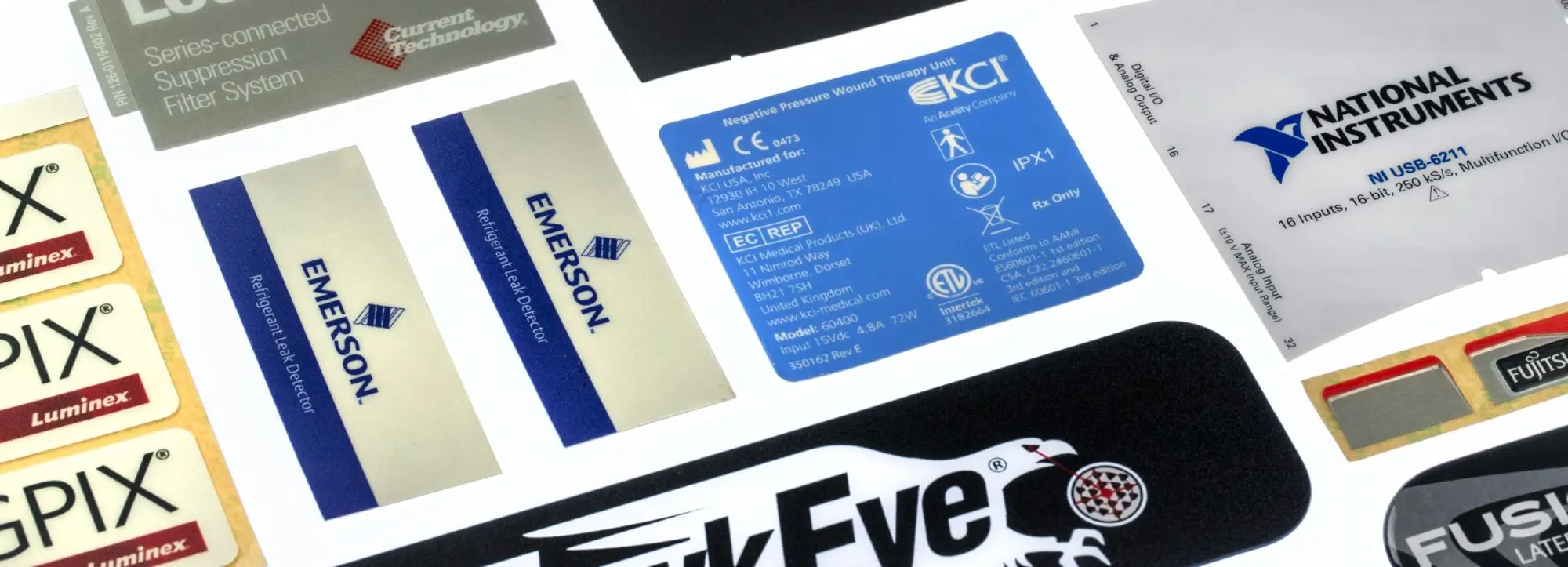

Products

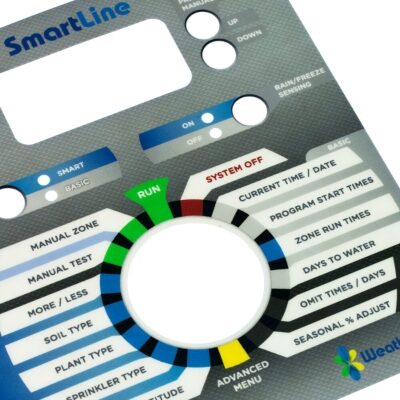

Decorative Nameplates and Overlays

These products typically use a sub-surface printed polycarbonate.

- Polycarbonate comes in three main finishes: velvet, gloss and hard coat with gloss levels ranging from 10% to 12%.

- Because the material is sub-surface printed, the labels are scratch-and-chemical resistant.

- Typical thicknesses are .005 to .030, making the labels extremely easy to apply.

- Polycarbonate material can be printed using many different methods including screen print and digital.

- Tolerances for nameplates and overlays made from polycarbonate are typically +-.010.

When additional heat and chemical resistance are required, many customers change from polycarbonate to Autotex polyesters. Polyester is a better choice for higher heat, harsher chemicals and greater number of actuations for membrane switches. Polyesters typically can handle 2,000,000 actuations where polycarbonate is rated for 200,000.

Whether you use polycarbonate or Autotex polyester, 3M is the best choice for adhesives. 3M manufactures a wide range of adhesives designed to adhere to metals, high surface energy plastics and low surface energy plastic with smooth and rough textures. The most used 3M adhesives are 200MP and 300lse family of adhesives. These adhesives come in both a .002 and .005 thickness.

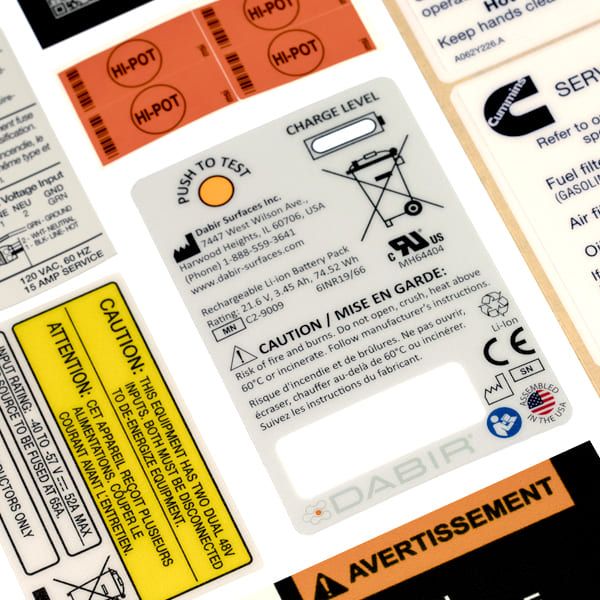

Information Labels

These labels typically include warning/caution, UL, wiring diagrams and any type of information label. 2 mil pressure-sensitive polyester is the best choice for these types of labels. That's because:

- Polyester does not shrink

- More chemical and heat resistant than polycarbonate or vinyl

- Comes in white, clear, shiny silver, matte silver and brushed silver

- Comes with a .001 or .002 adhesive already on the film so does not need to be added like polycarbonate

- Costs less than polycarbonate but slightly more than 4 mil pressure-sensitive vinyl

- Since it comes with adhesive these labels are typically top printed and to make them chemical/scratch resistant the labels are laminated with a .001 polyester over laminate.

- Laminate finishes are clear gloss, matte and velvet

- By adding a UV polyester laminate these labels will be rated for 5 years outdoors.

Information labels can also be made out of 4 mil pressure-sensitive vinyl. Vinyl is used when:

- Label needs to conform to an irregular shape

- Lower price point

- Has lower chemical and heat resistance than polyester

- Vinyl will shrink

In most cases used as a lower cost alternative to polyester.

Materials

Sub-surface Polycarbonate

Polycarbonate is the most popular material for designing decorative nameplates and overlays. Sub-surface printing creates an extremely durable label. Because polycarbonate does not come with an adhesive already on it, MSI is able to customize the adhesive used for the surface the label will be applied to.

3M makes a full range of adhesives designed to adhere to metals, high surface energy plastics and low surface energy plastics. The most common 3M adhesives used are the 200MP (3M467MP-.002, 3M468MP-.005) and 300lse (3M9471lse-.002, 3M9472lse-.005) families of adhesives.

Some features of polycarbonate are:

- Good chemical resistance

- Temperature range: -40 – 275F

- 200,000 actuations

- Thicknesses: .005, .007, .010, .015, .020, .030 (standard)

- Finishes: Velvet, Gloss, Hardcoat (added scratch resistance): 100%, 90%, 75%, 55%, 35%, 12% gloss levels.

Adhesives available:

- 3M200MP: 467MP-.002, 468MP-.005

- 300lse: 9471lse-.002, 9472lse-.005

Sub-surface Autotex Polyester

The difference with Autotex Polyester compared to Polycarbonate is added chemical and heat resistance. Features include:

- Excellent chemical resistance

- Temperature range: -70 – 302F

- 2,000,000 actuations

- Thicknesses: .005, .006, .007. .008, .010

- Finishes: Gloss, fine texture, velvet, steel, anti-glare, soft touch

2 mil Pressure-sensitive Polyester

2 mil pressure-sensitive polyester is typically used for information labels such as:

- Warning/Caution

- UL

- Wiring Diagrams

- Instruction

- Tamper-evident

- Variable Data

Features of 2 mil pressure-sensitive polyester include:

- Excellent chemical resistance

- Temperature range: -40 – 275F

- No shrinkage

- Colors: White, clear, shiny silver, gloss matte silver and brushed silver

- Laminates: Gloss, matte, thermal printable polyester and velvet

4 mil Pressure-sensitive Vinyl

4 mil pressure-sensitive vinyl is typically used as a low-cost alternative to 2 mil polyester for information labels such as:

- Warning/Caution

- UL

- Wiring Diagrams

- Instruction

- Tamper-evident

- Variable Data

Features of 4 mil pressure-sensitive vinyl include:

- Average chemical resistance if laminated with a polyester laminate

- Temperature range: -40 – 176F

- Colors: White, frosty clear, black and yellow

- Laminates: Gloss, matte, thermal printable polyester and velvet

2 mil Pressure-sensitive Thermal Polyester

2 mil pressure-sensitive thermal polyester has a special top-coating that allows our customers to print their own variable data labels in house at the time of manufacture. Manufactures will take either a partially printed or blank labels and add information such as:

- Serial number

- Bar code

- Date of manufacture

- Model number

Features of 2 mil pressure-sensitive thermal polyester include:

- Good chemical resistance when printed. Need an additional laminate to be permanent

- Temperature range: -40 – 275F

- No shrinkage

- Colors: White, clear, gloss, matte, silver