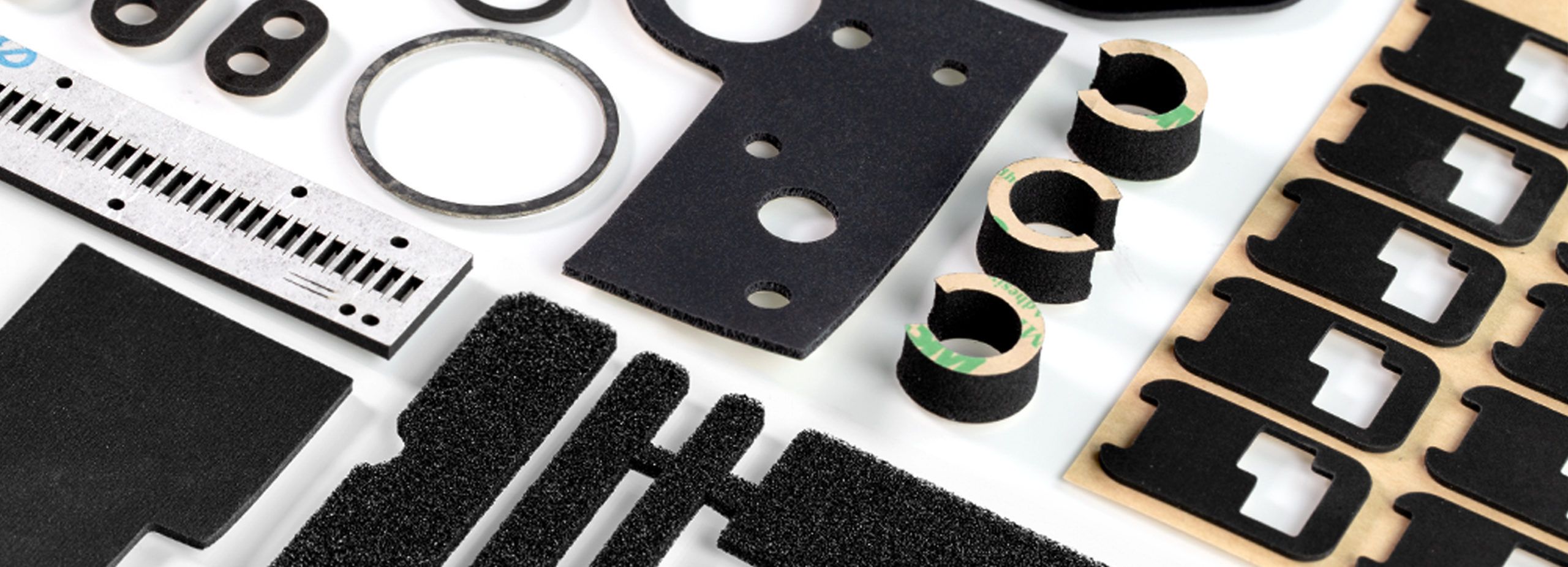

Gasketing & Sealing

Custom Gasket Manufacturing

Custom gasketing and sealing that drives production efficiency

Marking Systems, Inc. offers custom gasket manufacturing for a wide range of industrial applications. We can produce and die cut gaskets with tight tolerances to ensure your production process consistently meets precise requirements with every run. Whether you need custom rubber gaskets, silicone gaskets, foam gaskets or would like help developing a custom gasketing solution, we’re here to help. Our technical expertise, material converting services and rapid prototyping capabilities combine to make Marking Systems the complete one-stop shop for all your custom gasket manufacturing needs.

Superior custom gasket manufacturing capabilities

We develop gasketing and sealing solutions to your exact specifications using the highest quality materials available to ensure peak performance in your unique application.

Scroll down for more information on the various types of gasketing & sealing available.

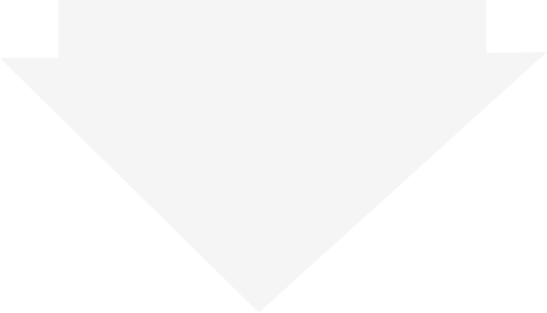

FOAM GASKETS

Many of our manufacturing customers value foam gaskets because of their versatile performance characteristics. We offer several types of foam gaskets to help you select the optimal material for your application.

Urethane

Microcellular urethanes provide durable, long-term performance in industrial applications. They can also provide excellent sealing, cushioning and vibration dampening performance. They are low-outgassing, non- fogging, non-corrosive, flame resistant, chemical resistant and will not become brittle. These microcellular materials are easy to fabricate, have a broad temperature range, and have a very low compression set and excellent compression force deflection performance compared to other materials. Common microcellular urethanes are Rogers Poron and 3M EAR Isoloss LS foams. As a Rogers Converter and 3M Preferred Converter, we purchase both products directly from the manufacturer, which provides us with competitive pricing and gives us access to many technical resources that are not available to other companies.

Silicone Foam

Cellular silicone such as Rogers Bisco foams and Saint Gobain NorSeal products are high-performance, very low compression set materials. They can provide superior sealing characteristics while returning to almost 100% of its original thickness and maintaining its compression force deflection. These foams are easy to fabricate both with and without adhesive. Our proprietary priming process even allows us to laminate silicone materials to less expensive acrylic adhesives. Silicone foams are resistant to extreme temperatures, which makes them ideal for high-heat applications, such as heat shields, fire stops and sealing applications close to engines and other elevated temperature spaces requiring a UL flame rating. Additionally, they are resistant to many chemicals, UV exposure and ozone.

Closed Cell Sponge

Materials such as Neoprene, EPDM, Nitrile and SBR can often be a cost-effective option for sealing and cushioning. Manufactured in bun form, these closed cell sponge materials can then be skived to any thickness, which can be helpful when needing a critical material thickness that may not be a standard size for some other cast or extruded roll products. These materials are resistant to UV exposure, grease, oil and many other chemicals, which makes them a great low-cost solution for outdoor applications.

RUBBER GASKETS

Solid rubber gaskets are commonly used in a variety of industries. While the function of most rubber gaskets is similar, they are not universal. The specific rubber material and gasket style may vary widely depending on the application.

Solid Silicone Rubber

Silicone is the most common synthetic rubber compound. It has a wide temperature range, from -100°F up to 500°F. It is resistant to many chemicals and oils at normal temperatures, but at high temperatures it is superior to other solid rubber products. The tensile strength, tear strength, elongation and compression set of silicone rubber are far superior to conventional rubbers. While more expensive than most other solid rubbers, silicone can be a great material choice for many applications.

Neoprene Rubber

Neoprene has good resistance to chemicals, water, heat, flames, oxygen and ozone. It has better resistance to water, solvents and heat than natural rubber. The material performs well when exposed to UV and other outdoor elements, so it ages well and will not have to be replaced as often as some other rubber materials.

EPDM Rubber

EPDM rubber gaskets are more resistant to wear from abrasion and are formulated to resist harsh chemicals such as acids and alkalis. EPDM gasket material is ideal for applications involving hydrocarbon oils and petroleum products, which are known to produce swelling in many other gasket materials.

Nitrile Rubber (Buna-N/NBR)

Nitrile rubber, also known as Buna-N and NBR, is the most widely used elastomer for gaskets and seals. Its properties provide excellent resistance to oils, solvents, gasoline and petroleum-based fluids. Nitrile rubber functions well in temperatures ranging from -40°F to 212°F.

Viton

Viton gaskets are made of high-performance fluoroelastomers that provide outstanding resistance to heat. These rubber gaskets generally support temperatures from 15°F to 400°F and are suitable for applications that reach 500°F intermittently. Gaskets made of Viton also provide excellent resistance to oils.

Natural Rubber (Gum Rubber)

Natural rubber gaskets provide superior dynamic sealing. They have a low level of damping and good low temperature properties, and mate well with metal surfaces. Natural rubber seals also resist tear and abrasion and can resist shear and compression for long periods in the absence of tension.

SBR (Red Rubber)

SBR is a copolymer of styrene and butadiene and has properties similar to natural rubber. It has good abrasion resistance, excellent impact strength and a high tensile strength. The temperature range of SBR is -40°F to 180°F.

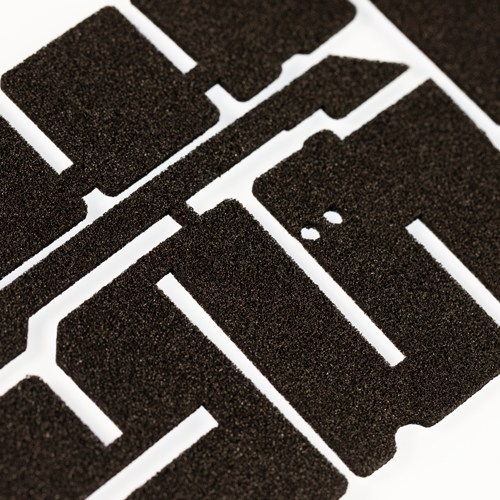

SPECIALTY

There are many specialty gasketing materials used for unique applications, whether it requires resistance to certain chemicals or fuels, higher than normal abrasion resistance, or a low coefficient of friction. We can help you create a custom gasket and sealing solution using materials like felt, cork, PTFE, electrically-shielded, conductive and insulating materials with high dielectric strength.

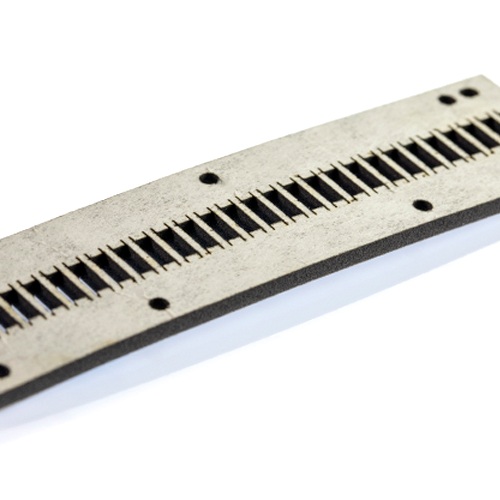

WORK WITH US!

When you partner with Marking Systems, you get custom gasket manufacturing services delivered with unparalleled precision, quality and professionalism. We have more than 50 years of experience in the converting services and product label industry, and we employ a wide variety of techniques and technologies to make sure you have the best experience possible.

Contact us today to get started on your next custom gasket manufacturing project.