Custom Overlay Manufacturing

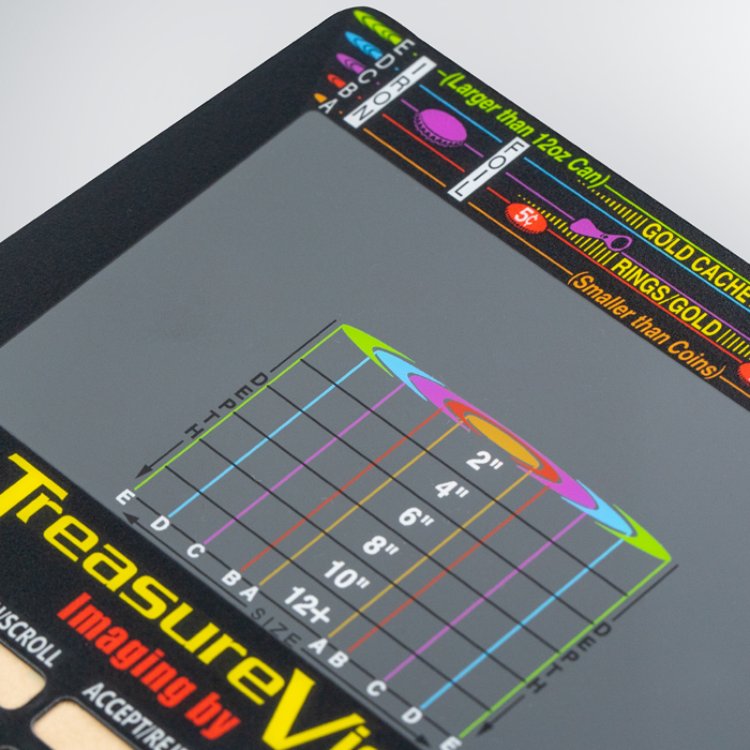

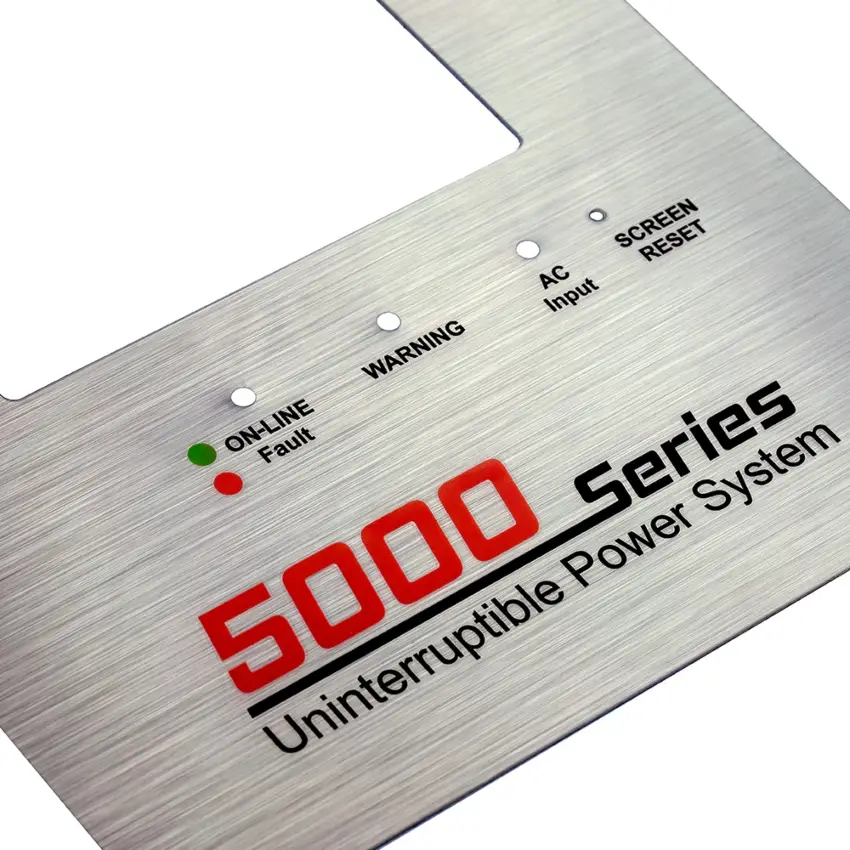

Custom overlay manufacturing is one of the main parts of our business. Overlays are critical and give your product its visual representation to your end user, They are oftentimes your products “first impression” and give it the “look.” Overlays are commonly the most recognizable component on your product directing the end-user around the keypad, often representing what each button will do. Custom color matching and branding are critical, and we’ve got the technology and experience to do the job. We can also help your designers choose the best materials and functionality for your application.

We work with any type of overlay, including screen printed, digital printed, custom textures, transparent inks, backlit/deadfronts, thick lenses, metallics and embossing.

Color matching is critical on any overlay and MSI is an expert in color matching. Using Datacolor Software and instrumentation ensures MSI can match your color and maintain consistency run to run. We always match color back to the standard to eliminate “color creep”.

Our expertise in adhesives means you never have to worry about your overlay falling off. We stock adhesives for hard - to - stick powder coat paint or plastics. Being a 3M Preferred Converter means MSI has a huge stock of 3M laminating adhesives such as 3M467MP, 468MP, 9471LE AND 9472LE to name just a few.

Ask our experts which adhesives is correct for your application.

Because overlays, along with nameplates are our main business, MSI also has a larger, wider stock a of polycarbonate and polyester sheets and rolls than any other printer in the label industry.

We know polycarbonate and Autotype polyesters.

Let the name and overlay experts at MSI help you design the perfect nameplate or overlay. Our Rapid Prototyping program means you get 10 samples in 1-2 weeks for a low lot cost starting at $250.00.

Scroll down for more information on the various types of overlays available.

SCREEN PRINTED OVERLAYS

MSI uses two main printing methods for overlays. Screen printing accounts for 65% of the overlays we print for several reasons.

- Screen printing is best for solid colors, typically large solid background colors.

- It’s also the best print method if your trying to match a specific brand color or trim piece. such as a plastic or metal bezel.

- Screen printing provides overlays with the highest level of opacity available. This is critical on overlays because of of display and LED windows.

- Screen printing is the best method to print the transparent windows used on many overlays.

- Screen printing is still the least expensive method for long runs due to the higher cost of digital inks and consumables.

Digital printing is used for the remaining 35% and is typically used for the following reasons.

- Digital is usually the best choice for overlays with more than 5 colors.

- Smaller runs are better to print digital because of the reduced set-up.

- Perfect color registration is attainable.

- In most cases digital printing is a better choice for very large outdoor logos.

Transparent colors, large solid colored backgrounds, large sized parts and color matching may not be the best choice for digital printing.

CUSTOM TEXTURE OVERLAYS

MSI is one of the few screen printers in the U.S. that still uses a UV nitrogen-cured custom texture.

We do this because nitrogen cured texture is the most scratch resistant texture available and is virtually indestructible. The nitrogen cured texture is more expensive but provides your overlay with increased durability.

Custom Texture is typically printed on a gloss material ( polycarbonate or polyester ) in order to give overlays a texture everywhere but the display or LED window. Like nameplates, the texture can also be used for aesthetic purposes to draw the customer’s attention to certain aspects of the design.

METALLIC OVERLAYS

MSI uses two main printing methods for overlays. Screen printing accounts for 65% of the overlays we print for several reasons.

- Screen printing is best for solid colors, typically large solid background colors.

- It’s also the best print method if your trying to match a specific brand color or trim piece. such as a plastic or metal bezel.

- Screen printing provides overlays with the highest level of opacity available. This is critical on overlays because of of display and LED windows.

- Screen printing is the best method to print the transparent windows used on many overlays.

- Screen printing is still the least expensive method for long runs due to the higher cost of digital inks and consumables.

DEADFRONT OVERLAYS

The term “Deadfronting” in the printing industry refers to an icon or feature that is hidden from view until an LED light illuminates the symbol or text. When the light source is on, the hidden graphics are revealed. When off, the graphics are hidden, or “dead”. This allows you to illuminate only the graphics or symbols in use at the time.

In contrast to the static graphic options of the past, dead front overlays give the benefit of a less cluttered look to your overlay.

If you have an overlay you think might benefit from “dead fronting” please contact your MSI SCR or sales rep and ask about our Rapid Prototyping Program. This innovative program makes it inexpensive, quick and easy to see physical samples before deciding to upgrade the look of your overlay.

THICK LENS

Thick Lenses are typically overlays that are .040-.125 thick. These overlays require very specialized printing, cutting and handling by the screen printer. The hard coat polycarbonate, while scratch resistant on the top, is very soft and scratchable on the print side. This means the overlays must be handles with extreme care as the parts are printed and cut. MSI has developed a production method that virtually eliminates rejects from scratches in the clear windows.

Using 3M laminating adhesives or VHB foam tapes, the thick lenses can achieve a watertight seal.

MSI cuts the thick lenses with a 400 watt Coherent Industrial Laser with camera controlled registration.

EMBOSSED OVERLAYS

MSI uses both cold and heated methods to emboss overlays. Depending on your application and specifications, MSI can emboss the overlay up to 1.5-4 times the thickness of the material. MSI can emboss both polycarbonate and polyester in material thicknesses ranging from .005-.030.

When you need embossing on your overlay, polyester is the material choice. Polyester is approximately 10 times more durable than polycarbonate. Polyester is rated for 2,000,000 actuations compared to 200,000 for polycarbonate.

If you have an overlay or nameplate that you would like to add embossing to, contact your MSI CSR or sales representative and ask about our Rapid Prototyping Program. This innovative program makes it inexpensive, quick and easy to see physical samples before deciding to upgrade the look of your overlay.