Our Label Color Matching Processes

Marking Systems is a global leader in color management for nameplates, overlays, labels, and membrane switches.

The world's leading OEM's have used our innovative label-printing solutions to consistently achieve the perfect color over 40 years. Our computerized systems for color measuring, matching, and quality control delivers every label printing order consistently and correctly.

STEP 1 - THE COLOR STANDARD

It all starts with the customer sending us a color standard to be matched.

This can be virtually any type of material but is usually a plastic or metal bezel.

STEP 2 - THE FORMULA

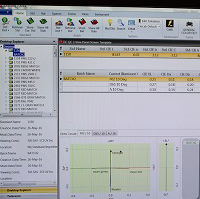

Marking Systems uses the latest high-tech tools from DataColor to determine the formula for the color match.

A bucket is marked for future identification.

STEP 3 - COLOR MATCH APPROVAL

Once the correct color match is achieved, we prepare a two-part card to share with the customer. If approved, they tear the card in two halves. One is signed and sent back to Marking Systems and the other is kept by the customer for future reference.

We file the original color standard along with the color approval card in a light-blocking envelope and maintain it in our color standards file.

STEP 4

Marking Systems owns two of the most technologically advanced digital blade cutters in the USA. These cutting presses use camera registration and an advanced cutting blade to cut the most intricate polycarbonate overlays and nameplates in prototype and small run quantities.

They register and cut dimensions to + - .010 on polycarbonate materials up to .015 thick. Unlike lasers, the blades cause no charring of the polycarbonate materials on light-colored backgrounds.

STEP 5

A high-quality nameplate that appears to be molded into the surface of the product.

Our quality department makes sure each future run of your product label looks exactly the same as the first.