Custom Industrial Nameplates

At MSI, we are a custom industrial nameplate manufacturer. Product identification is a crucial part of most any industry, and nameplates not only do that job, but boost your brand awareness in the process.

Nameplates are critical and give your product its visual representation to end users. They are oftentimes your product's "first impression" to the end users. Nameplates are commonly the most recognizable component of your product. Custom color matching and tight tolerance cutting are critical, and we've got the technology and experience to do the job. We can also help your designers choose the best materials and functionality for your application.

We can create and design a variety of custom industrial nameplates, including screen printed, digitally printed, embossed, custom texture, transparent inks, metallic, poly domes, contour cut, thermal die cut and outdoor logos.

Color matching is critical on any nameplate and MSI is an expert in matching colors and being consistent run to run. Using Datacolor software and instrumentation ensure MSI can match your color and keep it consistent. In order to ensure each run of your nameplates are the same color, we always match each color back to the color standard. This eliminates "color creep."

Our expertise in adhesives means you never have to worry about your nameplate falling off. We stock adhesives for hard-to-stick-to powder coat paint or plastic. Being a 3M Preferred Converter means MSI has a huge stock of 3M laminating adhesives such as 3M467MP, 468MP, 9471LE and 9472LE to name just a few.

Ask our experts which 3M adhesive is correct for your application.

Because Nameplates and Overlays are our main business, MSI has a larger, wider stock of polycarbonate and polyester sheets and rolls than any other screen printer in the label industry. We know polycarbonate and we know Autotype polyesters.

Let the Nameplate and Overlay experts at MSI help you design the perfect nameplate or overlay. Our Rapid Prototype Program means you get 10 samples in 1-2 weeks for a low lot cost starting at $250.

Scroll down for more information on the various types of industrial nameplates available.

SCREEN PRINTED NAMEPLATES

MSI uses two main printing methods for nameplates and overlays screen printing and digital printing. MSI uses screen printing for approximately 65% of the overlays and nameplates we produce. We use screen printing for several reasons.

- Screen printing is the best for printing solid colors, typically large solid background colors. It is also the best printing method when you would like to match a specific color such as a plastic or metal bezel.

- Screen print provides nameplates and overlays with the highest level of opacity available. This is critical on overlays because of the display and LED windows.

- Screen printing is the best method to print the transparent colored windows used on many overlays and membrane switches.

- Screen printing is still the least expensive printing method for long runs of overlays and nameplates. This is due to the high cost of digital inks and consumables.

DIGITALLY PRINTED NAMEPLATES

Digital printing is used for approximately 35% of the orienting that MSI currently does and is typically used for the following reasons.

Four-color process and gradients in the art design. Digital is typically the best choice for overlays or nameplates that have 5-6+ colors. Smaller runs are better to print digital because of the reduced setup. Perfect color registration is a benefit with digital printing. Digital prints all colors in perfect butt registration that screen printing cannot duplicate. Finally, in most cases, digital printing can print very large outdoor logos much easier than screen printing.

Transparent colors, large solid-colored backgrounds, large-sized parts and color matching are areas where digital may not be the best printing method.

CUSTOM TEXTURE NAMEPLATES

MSI is one of the few screen printers in the U.S. that still uses a UV nitrogen-cured custom texture. We do this because nitrogen-cured texture is the most scratch-resistant texture available in the market and is almost indestructible. The nitrogen-cured texture is more expensive but provides your nameplates and overlays with increased durability.

Custom textured is typically printed on a gloss material (polycarbonate or polyester) in order to give the overlays a texture everywhere but the display or LED windows. Like nameplates the texture can also be used for aesthetic purposes to draw the customer’s attention to certain aspects of the design.

If you have an overlay or nameplate that you think would look better with custom texture please contact your MSI CSR or sales representative and find out about our Rapid Prototyping Program. This innovative program makes it inexpensive, quick and easy to upgrade the look of overlays or nameplates.

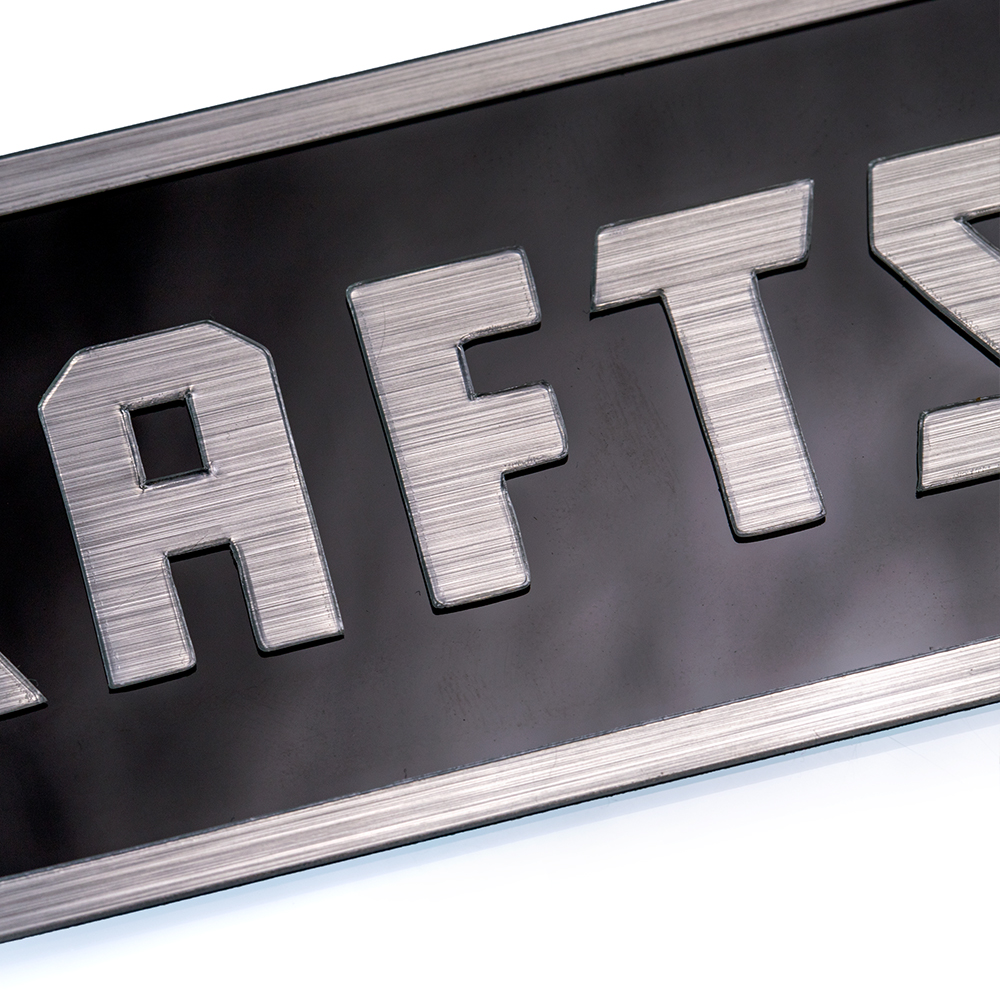

METALLIC NAMEPLATES

MSI has developed a production method to enhance our polycarbonate overlays with a beautiful Metallic look. Because everything is sub surface, these products are incredibly durable and good looking. Depending on your design this enhancement can be used with either screen or digital printing.

MSI has several different looks available and in stock.

If you have an overlay you think would look better by using a transparent ink, contact your MSI CSR or sales representative and find out about our Rapid Prototype Program. This innovative program makes it inexpensive, quick and easy to upgrade the look of any overlay.

2MIL POLYESTER NAMEPLATES

2mil polyester is an inexpensive material for producing attractive Nameplates. The Material is very versatile and durable. In combination with lamination, these labels can withstand high heat, chemicals and scratches.

Standard laminations include, gloss, matte and velvet. These laminations come in both an indoor version and a UV extended outdoor version.

POLY DOME NAMEPLATES

Poly dome, domes, domed or bubble Nameplates are an excellent upgrade for any high-end Nameplate. The polyurethane doming material is UV and chemical resistant.

Domed Nameplates are an excellent choice for indoor and outdoor applications.

Domed Nameplates can be screen or digital printed and are typically cut using steel rule dies. A big advantage to doming is it does not require any additional expensive tooling like injection ,molding.

EMBOSSED NAMEPLATES

MSI uses both cold and heat methods to emboss overlays. Depending on your application and specifications, MSI can emboss the overlay up to 1.5-4 times the thickness of the material. MSI can emboss both polycarbonate and polyester in material thicknesses ranging from .005-.030.

If you have an overlay or nameplate that you would like to add embossing to, contact your MSI CSR or sales representative and ask about our Rapid Prototyping Program. This innovative program makes it inexpensive, quick and easy to see physical samples before deciding to upgrade the look of your overlay.

CONTOUR CUT NAMEPLATES

This is an easy and cost effective design technique to enhance the look of any Nameplate. By giving the Nameplate a shape, it makes it look less like a simple label. Many of our OEM customers will put a recessed area into the bezel. When the label is applied the recessed area gives the label the look of being molded into the product.

If you have an Overlay or Nameplate that you think would look belter with a Contour Cut, contact your MSI CSR or sales representative and ask about our Rapid Prototyping Program. This innovative program makes it inexpensive, quick and easy to see physical samples before deciding to upgrade the look of your overlay.

TRANSPARENT INK NAMEPLATES

Transparent Inks are typically used for aesthetic purposes to enhance the appearance of your Nameplate. Printed over a metallic finish, Transparent Inks can provide a beautiful enhancement to any Nameplate.

If you have a Nameplate that could be enhanced by incorporating a Transparent Ink contact your MSI CSR or sales representative and find out about our Rapid Prototyping Program. This innovative program makes it inexpensive, quick and easy to upgrade the look of any Nameplate.

THERMAL DIE CUT NAMEPLATES

Thermal Die Cut have two primary applications, replacing direct print on a bezel or enclosure and for large outdoor company logos. In both cases Thermal Die Cut do not look like a label but rather look like the have been painted on the surface By using on a bezel rather than direct printing our customers save the hassle of sending their bezel or enclosure out to a supplier or they can stock blank enclosures and mark the enclosure as orders come in. This reduces inventory and eliminates getting stuck with wrong printed enclosures.

Does a Thermal Die Cut Decal sound interesting? If so, ask about our Rapid Prototyping Program. This innovative program makes it inexpensive, quick and easy to see physical samples before deciding to upgrade the look of your Nameplate.

OUTDOOR LOGOS

MSI was started by Henry Van Beber in 1971. Henry got his start working for 3M’s Commercial Solutions Division where he sold the 7 year vinyl used for tractor trailer rigs.

If you have a need for long lasting decals or label for your outdoor equipment, call us. MSI has manufactured long-lasting decals and labels for over 50 years. WE can help you match the perfect materials and adhesives for your brand.

If you have a outdoor decal or label requirement please contact your MSI CSR or sales representative and find out about our Rapid Prototyping Program. This innovative program makes it inexpensive, quick and easy to upgrade the look of any Nameplate.