Cool Solutions for Hot Tech: The Role of Custom Die-Cut Thermal Solutions

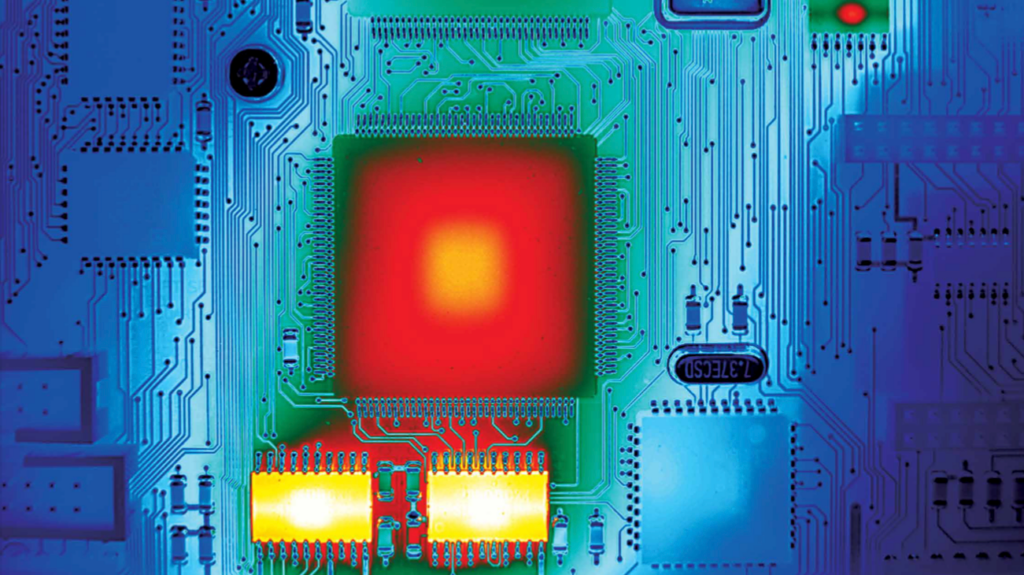

As personal electronics, including cell phones and wearable devices like smartwatches and fitness trackers, continue to shrink in size, the need for managing heat inside these devices becomes increasingly critical. These electronic devices generate heat, and in order to prevent damage to the processors and other sensitive internal components, that heat must be effectively managed and dissipated.

In the past, this was primarily accomplished through the use of heat sinks. However, heat sinks are heavy, expensive, and demand a significant amount of internal space – space that is simply unavailable in your average cell phone or smartwatch.

The reduced size and weight of these devices presented a unique challenge to the electronics industry. In the early days of cell phones and other wearable devices, heat management was often inadequate. These devices would frequently overheat, leading to shutdowns and, in some cases, permanent damage. Something had to be done to effectively manage this excess heat and prolong the lifespan of these devices.

Thermal Solutions

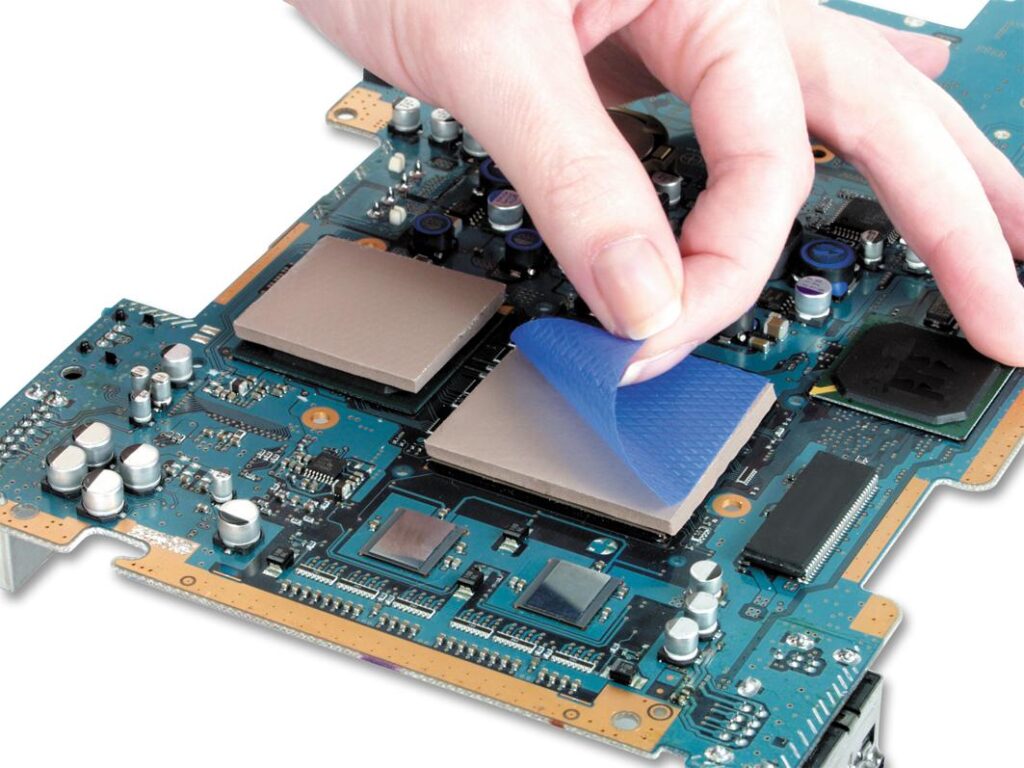

Thermal management materials, including gap pads and thermally conductive foil tapes, emerged as the solutions that the industry needed. These materials are thin, lightweight, and do not necessitate the bulk of a traditional heat sink. Furthermore, they are relatively inexpensive when you consider their overall performance. These materials can be used either independently, replacing the need for a heat sink, or in conjunction with a heat sink to enhance its performance.

Thermal gap pads and thermal tapes can be custom die-cut to provide a straightforward drop-in solution for your device. In contrast to thermal grease or thermal epoxy, you don’t have to worry about whether your assembly team is properly dispensing the correct amount of product, and you can eliminate concerns about unwanted messes or the need for cleanup.

Opting for a custom die-cut thermal management solution will enhance efficiency on your production line, saving you time and money, and will also contribute to improved product performance and longevity.

Quality

Marking Systems Die-Cut (MSD) is a leading provider of precision die cutting services, specializing in tight tolerances and high-quality results.

With our state-of-the-art equipment and experienced technicians, we deliver intricate cuts with exceptional accuracy, ensuring your components meet the highest standards. Our capabilities extend to a wide range of materials and processes.

If you are in the process of developing a device and are concerned about thermal management issues, we encourage you to contact us.