Precision Die-Cutting

Precision Die Cutting

Consistent, Precise Cuts Every Time

Best-in-Class Die Cutting Equipment

Our custom die cut manufacturing services use some of the most advanced equipment available on the market today. We designed our fleet with five types of machinery to offer our customers greater flexibility to match the ideal process to your unique application.

Scroll down for more information on the various types of Die-Cutting available.

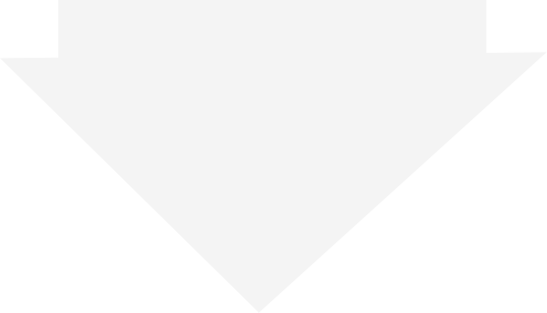

PRECO

Preco presses run at speeds up to 2,000 inches per hour with virtually perfect camera registration using X, Y and Theta alignment. The high-precision depth adjustment and roll-to-roll operation of these machines makes them ideal for kiss cutting parts to a release liner. We have three Preco cutting lines that are very cost-effective for medium to large runs of parts made with elastomeric materials such as foams, sponge, solid rubber and VHB.

DIGITAL BLADE

Marking Systems owns two highly advanced Zund digital blade cutters. These machines use camera registration and have the option of either a drag knife or reciprocating blade to cut the most intricate parts in prototype and small run quantities. They can register and cut dimensions to tolerances as tight as +/- .010”. But unlike lasers, the blades don’t cause charring.

CLAMSHELL

Our five clamshell presses are ideally suited for small to medium-sized orders. These sheet-fed presses utilize a Spartanics Optical Registration System that can guarantee +/- .030” cutting tolerance for elastomeric materials. These highly versatile presses have the ability to use multi-stage dies and even a heating element, which makes them an important part of our die cutting fleet.

ROTARY PRESS

Our rotary press is primarily used for large high-volume orders. Unlike a clamshell press or Preco, which use a flat steel rule die, rotary presses use a machined cylinder tool which cuts as it spins while material is pulled through at speeds up to 300 feet per minute. Rotary presses can laminate in-line, remove waste and dunnage, apply selective adhesive, and can even automate some basic part assemblies. For high volume orders, the rotary press is a great cost-effective solution.

LASER

Our six flatbed lasers are perfect for both rigid materials and elastomeric materials like foam, sponge, solid rubber and VHB. They require no tooling, so this is where many projects begin as designs are still being developed. Without the need to compress materials like a traditional die cutting press, we are able to cut delicate thin-wall parts with no concavity. These lasers use an advanced camera registration system and can easily hold +/- .010” tolerance on even the thickest, most intricate parts.

GALVO LASER

Anytron III, a 250W roll-to-roll Galvo Laser, is utilized for both MSI and MSD customers, as it can quickly and efficiently cut a wide range of materials. The Galvo Laser generates maximum speed at 147 feet per minute. There are no consumables, maintenance is easy, and it has multiple cutting functions such as kiss cut, through cut, marking, perforation and even sequential number marking or cutting, depending on your needs.

This new line of equipment will give us a one-stop solution for laminating, laser cutting, waste removal and slitting, which greatly improves productivity.

Galvo Laser Benefits Include:

- 15,000 labels can be cut within one hour with no retooling

- The combination of the latest laser technology and vision system guarantees the quality of the labels

- Time and cost can be reduced by improved performance efficiency

- Cutting and marking can be performed simultaneously

- Reduced cost – No tooling required

- Full and half cuts can be performed simultaneously

- Can handle a variety of materials such as polyester, paper, abrasives, foam, rubber, neoprene, PET, etc.

- Specializes in reflective film cutting, which cannot be done on knife cutters. Knives are traditionally used for glass fiber material, but knives need to be changed often, which increases cost and decreases productivity

Work With Us!

MSI is the expert in precise, exact cutting, every time. Call us today!