Die-Cut Converting

PRECISE CUSTOM DIE CUTTING THAT DRIVES MANUFACTURING EFFICIENCY

FOR NEARLY ANY INDUSTRY

Marking Systems, Inc. has the die cut converting solutions manufacturers and fabricators need to drive efficiency and speed production. We are experts in finding the best material for your application and have a lengthy history producing high-quality gaskets, insulators, bonding and fastening, EMI/RFI, thermal, vibration and cushioning and masking. We work side by side with our sister company, MSD, which specializes in die cut converting services and is also a 3M Preferred Converter. This means our customers have unique access to some of the most sought-after materials in the industry. We work daily with PORON gaskets, gap-pads, shielding materials, adhesives, bonding substrates and insulation. So, whatever your industry or application, we're your trusted partner for all of your die cutting needs.

Here’s a look at the solutions we specialize in. Click each one to see samples and learn more details, then call us to get started on your prototype.

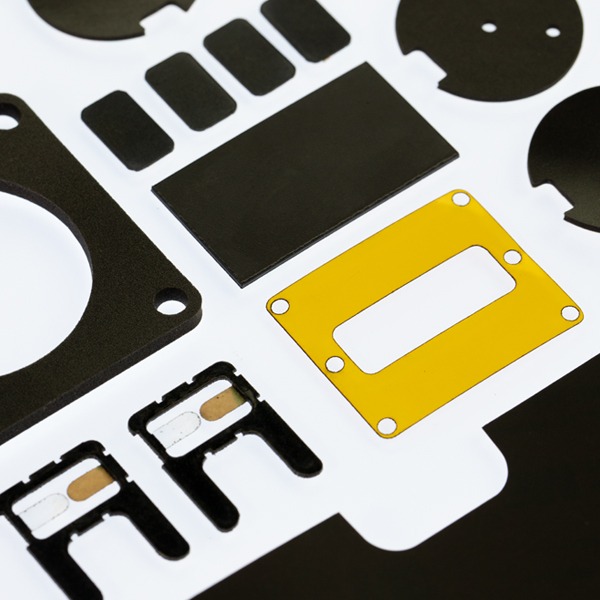

Gasketing & Sealing

We can produce custom gaskets for a variety of applications using foam, rubber and other materials, including specialty products.

Whether you need a gasket for sealing internal components or protecting a product from the outside environment, we’re here to help.

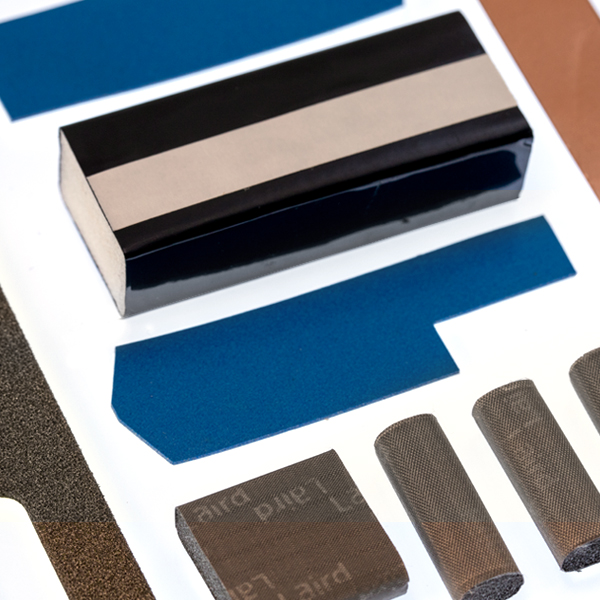

Vibration & Cushioning

Many machines and devices produce unwanted noise and vibration as they operate. This unwanted sound and vibration can wreak havoc on sensitive electronics and can create unnecessary noise pollution in many environments. Luckily, there are a number of products available to help manage these issues and keep your products operating quietly for long-term use. MSI/MSD manufactures die-cut components using highly engineered materials that are formulated for sound dampening, vibration damping, vibration isolation, and noise reduction.

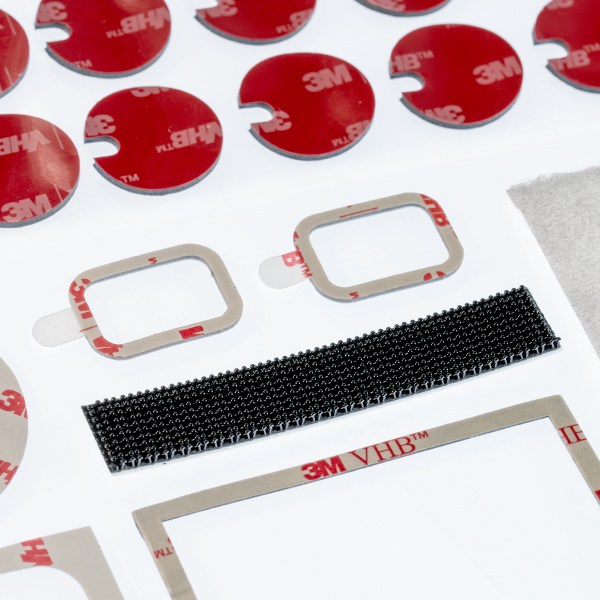

Bonding & Fastening

Enhance your design appearance with virtually invisible bonding — a potentially game-changing approach for your design concepts. Explore new possibilities and use new, innovative materials to improve the look of your products while optimizing performance, preventing bi-metallic corrosion and streamlining your production processes.

Laminating Adhesives

When choosing a laminating adhesive, there is no “one size fits all” solution. Each combination of substrates requires an adhesive that is engineered to bond to those two surfaces, as well as being able to withstand whatever environmental conditions it might be exposed to. Whether bonding high surface energy bare metal, powder coated or painted surfaces, low surface energy injection molded plastics or any other substrate, there is a unique adhesive engineered for that exact application.

Specialty Tapes

At MSD, we offer a variety of specialty tapes such as masking, safety and electrical tapes. Our die cutting presses produce custom parts for unique masking protection. Die cuts reduce manufacturing costs by providing precise, pre-cut pieces that eliminate hand-trimming and extra assembly time.

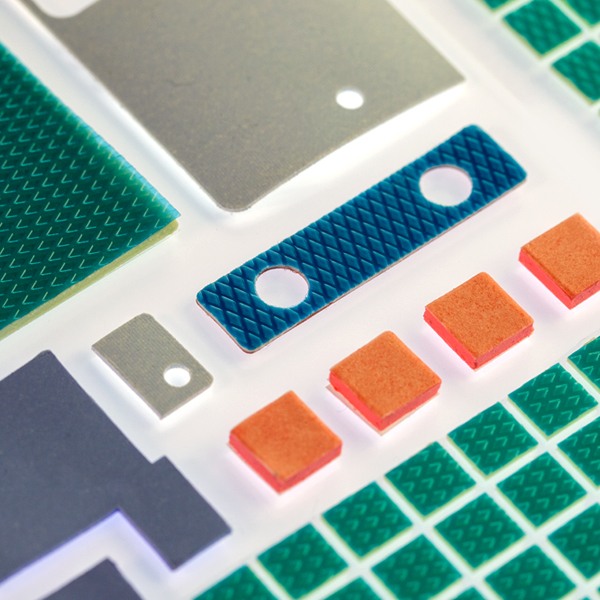

Thermal Management

As our world becomes more connected, everyone is using more electronic devices that require electrical and thermal management solutions to avoid failure in the field. We are highly skilled in providing die cutting services for thermal management materials such as gap pads, insulator pads, and thermal transfer tapes

EMI/RFI Shielding

With the use of wireless communications, now more than ever it is important to protect your product from wireless interference with other devices. Our experts will work with your team to determine the best die cut shielding option for your project.

Insulators

With so many insulation materials on the market, it can be overwhelming to determine what you need. Our team is highly skilled in helping you choose the best material and design an insulator for your unique application.

UNMATCHED MATERIALS EXPERTISE AND SOURCING

Do you need to resource or replace a hard-to-find or long lead-time material? We’re here to help. Since early 2020, we have helped customers find hundreds of alternative materials to keep their lines up and running during periods of disruption. Contact us to speak with one of our materials experts who can help solve your most pressing challenges.

WORK WITH US!

Marking Systems delivers die cut converting services with unparalleled speed, precision, quality and professionalism. We have more than 50 years of experience in the product label industry and employ a variety of die cutting techniques and technologies to ensure every piece in every production run is to your exact specifications.

Contact us today to learn more about how our die cut converting services can drive efficiency for your next project.