Invisible Ink On Labels: A Complete Guide

Recently, MSI helped our customer National Instruments test and certify an invisible ink. This ink can only be seen and scanned with a special reader using a black light. National Instruments wanted MSI to print an invisible 2D barcode with the overlay’s part number encoded in it.

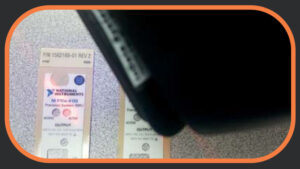

As you can see in the picture, on the left the product label overlay has a part number tab at the top for identification in production. Since this tab is thrown away after the overlay is applied, it becomes difficult to identify the part as it moves through the production system.

By using the invisible ink, National Instruments is able to track the parts through production without the customer being able to see the bar code in the field.

By using the invisible ink, National Instruments is able to track the parts through production without the customer being able to see the bar code in the field.

MSI’s R&D Director, Razvan Datcu, was able to work with the ink manufacturer to ensure a high-quality print and proper adhesion to the polycarbonate material. Regarding the bar code size, because of the limited space for the barcode, MSI and National Instruments decided on a 3 mm Data Matrix barcode for their product label.

The decision was based on the fact that the most popular application for Data Matrix is marking small items, due to the code’s ability to encode 50 characters in a symbol that is readable at 2 or 3 mm and the fact that the code can be read with only a 20% contrast ratio.

The invisible ink is perfect for applications involving counterfeit problems. The ink is versatile and can be screen printed on many different materials and applications.