CASE STUDY:

How 3M adhesives saved truck manufacturer time

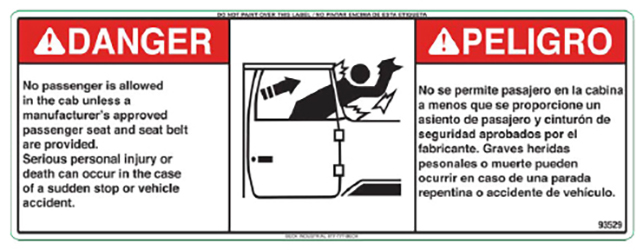

Warning and caution information labels are among the most important elements of your product. Whatever the device may be, users need to know how to operate it safely. Warning labels are their immediate, first line source of information. In extreme cases, it could mean the difference between life and death. For you, it means you need that label to stay put in all kinds of conditions. That’s where we come in. But, it’s not always easy. Each customer has unique challenges and situations that we need to work with in order for that warning and caution label to do its job. Here’s an example of how we helped solve an issue for one of our customers who manufactures concrete mixer trucks.

Challenge

Our client, a manufacturer of concrete mixer trucks, was concerned about a warning label that was to go on the fabric sun visor in the vehicle. It would be necessary to heat-form the label to adhere to the visor. It’s a lengthy process and they didn’t feel they had that kind of time. Their fix: A plastic heat visor. Great idea. No heat forming of the label required. They could make the visor on their production line, and they wanted a warning label that they could simply peel and stick, right there on the line. But that presented another problem: Adhesion. The plastic visor contained plasticizers that don’t play well with Pressure Sensitive Adhesives (PSA) ... which were on their labels. Why wouldn’t it work? A plasticizer is a chemical compound that is often added to other plastic materials to create a softer and more flexible feature to the base material. When a pressure sensitive adhesive is applied to a plasticized material, the plasticizer in the material will migrate into the adhesive. This causes the adhesive to soften and lose its bond strength over time.How We Solved It

Our R&D Manager worked with our 3M Converter Markets Specialists to determine the best adhesive for this application given that the surface had plasticizer chemicals. Our 3M Rep recommended a special acrylic adhesive that could hold up to the plasticizer properties — 3M F9467U Acrylic Adhesive. It is formulated to resist the effects of plasticizer migration for longterm bonding strength.

Results

The 3M F9467U Acrylic Adhesive worked great for our customer’s application. Being able to use a Warning label that they could peel and stick to the plastic visor saved them time and money compared to the lengthy process of heat forming the label. This is one more example of the importance of MSI being a 3M Preferred Converter. We had access to their experts right away in order to give our clients the solution they needed!

How We Solved It

Our R&D Manager worked with our 3M Converter Markets Specialists to determine the best adhesive for this application given that the surface had plasticizer chemicals. Our 3M Rep recommended a special acrylic adhesive that could hold up to the plasticizer properties — 3M F9467U Acrylic Adhesive. It is formulated to resist the effects of plasticizer migration for longterm bonding strength.

Results

The 3M F9467U Acrylic Adhesive worked great for our customer’s application. Being able to use a Warning label that they could peel and stick to the plastic visor saved them time and money compared to the lengthy process of heat forming the label. This is one more example of the importance of MSI being a 3M Preferred Converter. We had access to their experts right away in order to give our clients the solution they needed!

Our How 3M adhesives saved truck manufacturer time at MSI provide a clean, professional look that is made to last.

Interested? Intrigued? We can rapid prototype a model for you. Get started with your prototype by contacting us at MSI.

We’d love TO HELP YOU GET STARTED.