Invisible Ink, Clear Impact: MSI Boosts NI’s Production Efficiency

CHALLENGE

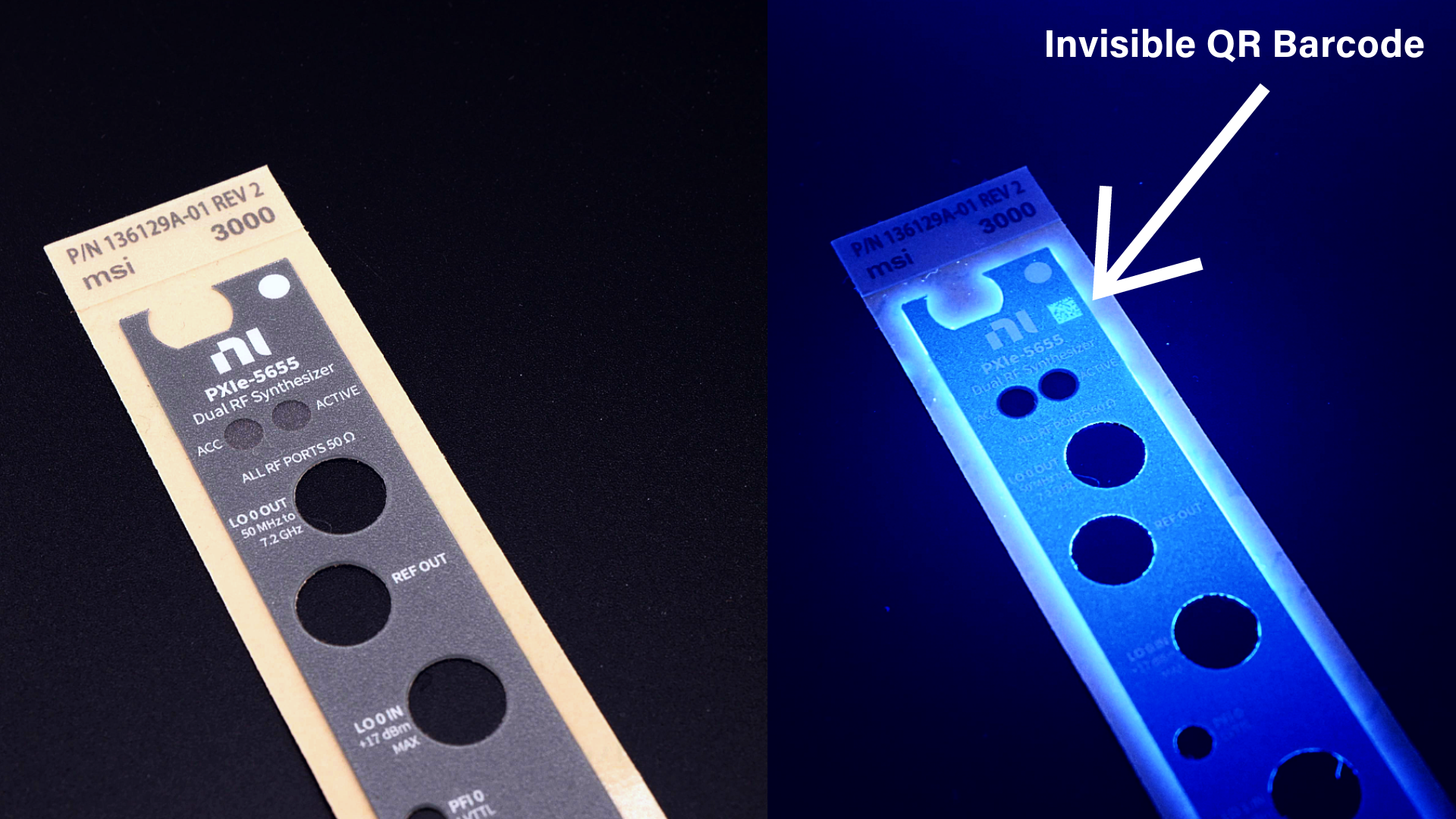

National Instruments (NI) faced a production challenge where operators were accidentally applying incorrect overlays to PCI cards. This was due to the difficulty in distinguishing between similar-looking cards based on their voltage input/output requirements.

HOW WE SOLVED IT

MSI, in collaboration with partners, developed a comprehensive solution to address this issue:

- Invisible Ink Formulation: A custom ink containing an optical brightener powder was created. This ink would only be visible under ultraviolet (UV) light, making the QR barcode invisible under normal lighting conditions.

- UV Barcode Reader Selection: A specialized reader with a custom UV light source was chosen to detect the invisible DataMatrix barcodes.

- Barcode Reader Modification: MSI’s R&D director, Razvan Datcu, worked with InData systems to modify a commercially available reader:

- Hardware: The reader was rebuilt to convert luminescent signals from the invisible QR barcode into signals readable by software.

- Software: Custom software was developed to translate the luminescent data into a standard QR code format, including error correction functionalities.

RESULTS

The invisible QR barcodes and modified barcode readers eliminated the possibility of applying incorrect overlays. Over five unique overlays could be created, each with a specific invisible QR barcode corresponding to the required voltage specifications. By combining invisible ink, specialized barcode readers, and software development, MSI helped NI achieve flawless application on their assembly line, significantly improving production efficiency and accuracy

MSI's solution provides a clean, professional look that is made to last.

Interested? Intrigued? We can rapid prototype a model for you. Get started with your prototype by contacting us at MSI.

CONTACT US TODAY WITH YOUR CHALLENGE!