Unleashing Efficiency: How Die-Cut Solutions and 3M VHB Can Boost Your Manufacturing Productivity

In today’s fast-paced manufacturing environment, every second counts. Streamlining your assembly process and maximizing production efficiency are crucial for staying ahead of the curve. At Marking Systems Die-Cut (MSD), we understand these challenges and offer innovative solutions to help you achieve your goals.

Beyond the Standard: Die-Cut Solutions for Efficiency

Traditional methods like screws, rivets, and welding often involve multiple steps, specialized tools, and can even create unwanted marks or limitations on design flexibility. This can lead to bottlenecks in production and hinder your overall efficiency.

MSD’s die-cut solutions offer a game-changing alternative, providing several benefits that directly contribute to increased productivity:

- Reduced Assembly Time: Pre-cut and customized components eliminate the need for complex assembly processes, allowing for faster and more efficient bonding.

- Simplified Application: Our die-cuts often feature user-friendly peel-and-stick application, minimizing the need for specialized equipment or training.

- Improved Labor Efficiency: By streamlining assembly, the use of die-cut components can free up valuable labor resources for other critical tasks.

- Reduced Waste: Pre-cut components minimize material waste, lowering costs and contributing to a more sustainable production process.

The 3M VHB Advantage: A Productivity Powerhouse

As a 3M Preferred Die-Cutter, we are experts in converting 3M VHB tapes into highly efficient solutions. This innovative double-sided acrylic adhesive tape boasts several features that further enhance your manufacturing productivity:

- Immediate Handling Strength: 3M VHB tapes provide immediate bond strength, allowing for faster processing and handling of components after application.

- Eliminates Drilling and Welding: Say goodbye to time-consuming and potentially hazardous drilling and welding processes. 3M VHB tapes offer a faster and more efficient alternative.

- Durable and Long-Lasting: With exceptional resistance to heat, chemicals, and UV light, 3M VHB tapes require minimal maintenance and ensure long-lasting product performance, reducing the need for rework or repairs.

Beyond the Benefits: Industries Experiencing Increased Efficiency

Die-cut solutions with 3M VHB tapes are making waves across various industries, significantly improving manufacturing processes:

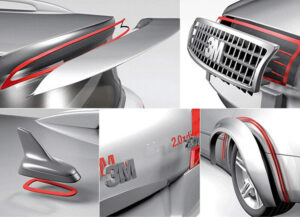

- Automotive/Aerospace: Replace time-consuming riveting and welding with faster and more aesthetically pleasing 3M VHB tape applications for interior components and trim.

- Electronics: Achieve seamless bonding of touchscreens and other delicate components while reducing assembly time and ensuring product durability.

- Medical Devices: Securely assemble medical devices with reliable and biocompatible 3M VHB tapes, streamlining production and ensuring patient safety.

- Outdoor Applications: Improve energy efficiency and building performance by using 3M VHB tapes for weatherproofing and sealing applications.

The MSD Difference: Your Partner in Efficiency

At MSD, we go beyond simply offering products. We are your dedicated partner in optimizing your manufacturing process for maximum efficiency. We offer:

- Expert Consultation: Our team of specialists will work closely with you to understand your specific needs and recommend the optimal die-cut solution with 3M VHB for your application.

- Customizable Solutions: We offer a wide range of materials and thicknesses to create die-cut components that perfectly fit your unique requirements.

- Quality and Consistency: We maintain the highest quality standards throughout every step of the process, ensuring reliable and consistent performance of your die-cut solutions.

Ready to unlock the power of die-cut solutions and 3M VHB to boost your manufacturing productivity? Contact Marking Systems Die-Cut (MSD) today today and let us help you streamline your process and achieve your production goals!